Aluminum Foundry important factors introduced in a direct manner

Wiki Article

The Significance of Metal Foundries: A Comprehensive Introduction of Their Effect On Production

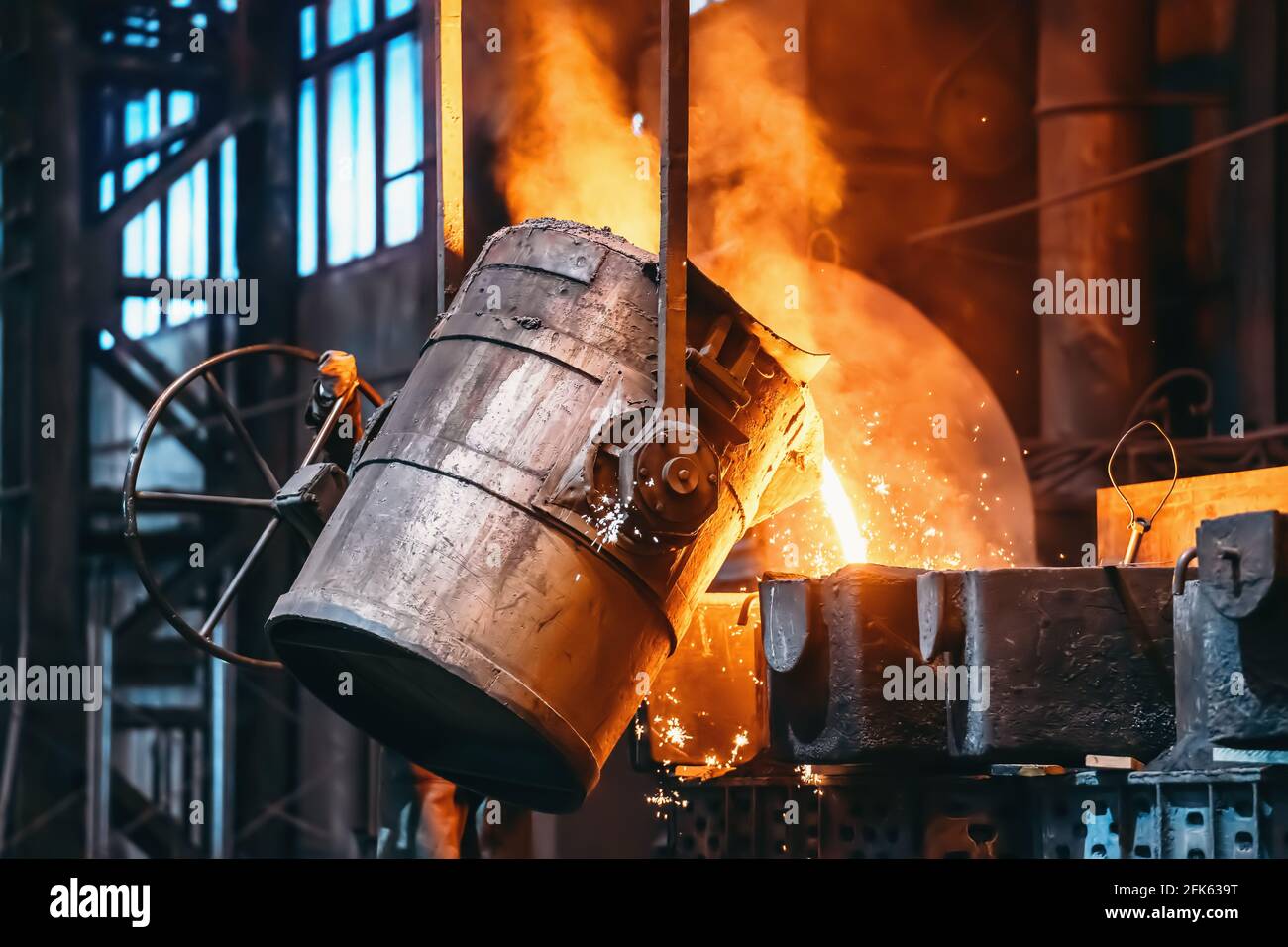

Metal shops are integral to the production landscape. They transform basic materials right into components that offer varied markets, from automotive to aerospace. Their experience in alloy formulation and spreading strategies assures the manufacturing of long lasting components. Nonetheless, the sector deals with difficulties that could improve its future. Understanding these characteristics reveals truth value of foundries in technological and financial contexts. What exists ahead for this vital field?The Role of Steel Shops in the Manufacturing Process

Usually forgotten, metal factories play a necessary role in the production procedure by transforming raw metals right into functional elements. These facilities concentrate on melting different metals, such as bronze, aluminum, and iron, and pouring them right into mold and mildews to produce parts for diverse sectors. The process begins with the careful selection of resources, making certain that only the greatest top quality steels are made use of. When thawed, the steel takes on the shape of the mold, strengthening right into parts that satisfy particular layout and efficiency requirements.Metal shops contribute significantly to sectors like vehicle, aerospace, and construction by offering vital elements such as engine blocks, gears, and structural assistances. Their knowledge in alloy formulation and casting methods enables producers to create intricate styles while keeping strength and durability. Consequently, metal factories not just assist in the creation of vital parts however also enhance the overall performance and performance of modern production.

Enhancing Production Efficiency With Advanced Techniques

Metal shops are significantly adopting sophisticated strategies to improve manufacturing efficiency and fulfill the expanding needs of numerous sectors. The implementation of automation and robotics has streamlined procedures, lowering manual work and increasing precision in metal spreading procedures. In addition, the combination of computer-aided layout (CAD) and simulation software program permits better planning and optimization of manufacturing operations, reducing waste and minimizing lead times.Lean manufacturing principles are also being used to improve and eliminate ineffectiveness source use. Factories are now concentrating on energy-efficient methods, such as utilizing waste heat recovery systems, which even more add to set you back financial savings and ecological sustainability. By accepting these sophisticated methods, metal factories are not just improving their operational performance however also enhancing item top quality, bring about higher customer satisfaction. As markets remain to develop, the capacity of shops to adjust to these developments will certainly be crucial for preserving competition in the marketplace.

Advancements in Metal Spreading Innovation

As the demand for precision and efficiency in manufacturing expands, innovations in steel spreading modern technology are changing the sector landscape. Advancements such as 3D printing and computer-aided layout (CAD) are making it possible for shops to produce complicated geometries with higher accuracy and rate. These methods decrease material waste and decrease lead times, fostering an extra sustainable production procedure.

Smart factory technologies, consisting of the Web of Things (IoT), help with real-time surveillance and information analysis, enhancing production efficiency and minimizing downtime. Collectively, these advancements are not only boosting the abilities of steel shops yet additionally setting the stage for the future of manufacturing, characterized by boosted dexterity and responsiveness to market demands.

The Economic Impact of Metal Foundries on Worldwide and neighborhood Markets

Steel shops play an important role in shaping financial landscapes, both locally and internationally. They create considerable job production chances and add to trade and export, strengthening general economic development. Furthermore, foundries support neighborhood company environments, fostering synergistic connections that improve community strength.Work Production Opportunities

Job development in the steel factory market considerably influences both local and international economic situations. These facilities supply various employment opportunities across different ability degrees, from competent labor to design and monitoring positions. The demand for metal components in industries such as automobile, aerospace, and building and construction drives the requirement for a robust workforce. As metal factories increase, they stimulate additional task creation in secondary industries, consisting of transport, logistics, and supply chain administration. Additionally, the financial security given by factory jobs contributes to neighborhood communities through enhanced spending and investment in facilities. In general, the steel foundry sector's capability to develop tasks not just enhances specific livelihoods however likewise reinforces local growth and resilience, showcasing its critical duty in economic advancement.

Export and Trade Contributions

A considerable section of the economic impact generated by shops stems from their payments to trade and export. Metal foundries play a necessary function in supplying parts for numerous industries, including auto, aerospace, and building, therefore boosting a nation's export abilities. By Visit This Link producing top notch castings and components, factories make it possible for neighborhood economies to compete on a global range. The export of these items not only boosts income yet likewise fosters worldwide partnerships and trade arrangements. Furthermore, foundries add to a beneficial trade equilibrium, which is crucial for financial security. The export tasks of metal shops stimulate technology and investment, ultimately enhancing their relevance in both worldwide and regional markets, driving development and financial strength.Citizen Organization Assistance Equipments

While neighborhood economies usually profit from the presence of steel factories, their effect prolongs beyond mere work development. These facilities add greatly to local business support group by cultivating a network of vendors, company, and supplementary markets. This interconnected community improves financial strength, permitting smaller sized companies to flourish together with larger foundries. In addition, steel factories often take part in community campaigns, investing in regional framework and education and learning, which additionally boosts financial growth. On a broader range, the existence of foundries can attract financial investment and skill, reinforcing the region's competitive advantage in global markets. Ultimately, the financial contributions of metal factories not only create straight work however likewise cultivate an encouraging environment for diverse regional business.Obstacles Encountering Steel Shops in the Modern Age

As the metal shop industry progresses, it deals with countless challenges that threaten its sustainability and competitiveness. One significant concern is the increasing cost of resources, which straight impacts production costs. Worldwide supply chain disturbances further exacerbate this issue, making it difficult for factories to keep consistent operations. Additionally, labor lacks offer a considerable obstacle, as skilled workers come to be limited in a quickly transforming technological landscape.Steel shops have to contend with rigid environmental guidelines that require higher conformity costs and financial investment in cleaner technologies. This shift requires foundries to adapt quickly, frequently stressing funds.

Competition from automated manufacturing processes and abroad manufacturing includes pressure, requiring local shops to run the risk of or innovate obsolescence. Addressing these difficulties is essential for the market to flourish in a affordable and significantly complex market setting.

Sustainability Practices in Metal Founding

In action to the obstacles faced by the industry, metal foundries are progressively embracing sustainability methods to boost their functional effectiveness and ecological obligation. These techniques consist of the implementation this website of energy-efficient modern technologies, such as electric induction furnaces, which reduce power consumption and greenhouse gas discharges. Furthermore, numerous shops are focusing on recycling scrap steel, lessening waste, and using environment-friendly products to decrease their ecological footprint.

Water conservation actions are likewise being prioritized, with systems created to reuse process water, thereby decreasing freshwater use. Foundries are investing in staff member training programs to advertise sustainable practices among employees, cultivating a society of ecological understanding.

Future Trends in the Steel Foundry Market

Shifting and arising innovations market needs are positioned to reshape the steel foundry market in the coming years. Increasing automation, driven by innovations in robotics and expert system, is anticipated to boost production performance and decrease labor prices. Metal Casting. Furthermore, additive manufacturing methods, such as 3D printing, are gaining grip, permitting even more facility and tailored metal components with lowered wasteSustainability will also play an important duty, with factories adopting greener techniques to minimize their ecological effect. The market is likely to see a surge in making use of recycled materials as raw inputs, aligning with global sustainability goals.

In addition, the demand for high-performance and light-weight alloys, specifically in the aerospace and auto industries, is anticipated to raise. This development will certainly require recurring investment in study and advancement, enabling metal shops to prosper and adapt in an affordable landscape. Overall, these patterns are readied to redefine the operational landscape of metal foundries.

Frequently Asked Concerns

What Sorts of Metals Are Frequently Utilized in Factories?

Typical steels used in foundries include iron, light weight aluminum, copper, and zinc. These products are preferred for their one-of-a-kind buildings, making it possible for diverse applications in sectors such as vehicle, aerospace, and construction, adding substantially to manufacturing procedures.Exactly How Do Metal Foundries Make Sure Product Top Quality and Uniformity?

Metal factories guarantee item top quality and uniformity via extensive quality assurance measures, including exact temperature regulation, product testing, and adherence to market standards. Regular assessments and knowledgeable craftsmanship further boost dependability and uniformity in production procedures.What Security Procedures Are Applied in Metal Foundries?

Steel foundries apply precaution such as personal safety equipment, ventilation systems, normal safety training, and strict adherence to security methods to minimize hazards. These methods aim to protect workers and keep a safe workplace.What Are the Job Opportunities in the Metal Foundry Sector?

Job opportunities in the metal foundry sector include functions such as factory workers, top quality control examiners, designers, machine drivers, and monitoring positions. These functions require different abilities, offering paths for development and field of expertise within the area.Just How Do Factories Manage Waste and Recycling of Products?

Shops take care of waste and recycling through processes like recovering sand, melting scrap steel, and utilizing by-products for power. These methods decrease ecological effect while advertising sustainability within the metal spreading market and boosting source effectiveness.Frequently overlooked, metal factories play an essential duty in the production procedure by changing raw steels right into functional elements. Metal foundries are increasingly taking on innovative techniques to enhance production efficiency and fulfill the growing needs of numerous industries. Steel foundries play a vital function in providing components for different sectors, including auto, aerospace, and construction, therefore enhancing a nation's find more information export abilities. In feedback to the difficulties faced by the sector, steel shops are significantly adopting sustainability methods to enhance their operational effectiveness and environmental duty. Aluminum Foundry. Profession possibilities in the metal shop industry include duties such as foundry employees, quality control inspectors, engineers, maker drivers, and management settings

Report this wiki page